Triaxial test is one of the most complicated standard tests performed in soil mechanics laboratories but now, thanks to new research and technology, it is possible to perform triaxial testing in automatic/PC-controlled mode. This article looks at the origins of triaxial testing systems and briefly outline the flaws associated with manual triaxial systems...leading to the 10 reasons why you should consider new the automatic way.

So let’s start and have a look at traditional systems.

Since the 1930s, geotechnical engineering practices have been relying on triaxial testing equipment to measure the stress-strain-strength properties of natural cohesive and compacted soils. These have also been used by Researchers to study soil behavioral issues (such as the influence of stress-strain history, strain rate, cyclic loading and so forth).

They were good in their times but…If you have been using standard triaxial testing systems, you have probably been facing the following issues:

Data acquisition is basic: this translates into low accuracy and lots of manual interventions to allow you to process and report testing data in the most accurate way (which is not very so).

Pressure sources are independent and require a lot of manual set-up. These include self-compensating mercury pots, compressed air, oil and water pumps as well as low resolution volume-change measuring devices.

Your lab is running out of space dedicated wall panels are needed to fit manual valves and air regulators taking up precious space in your lab plus making standard systems complex to set-up.

Manual triaxial systems are noisy: cell and back pressure lines require the use of compressed air which in turn is produced by an external compressor that is often noisy but requiring regular maintenance.

What does all this mean?

Well… productivity is low, testing accuracy unreliable and business growth limited.

As technology advances, automation across industries allows for fewer mistakes, faster production, more efficient processes, and greater accuracy, reliability, and measurability overall. For many years, geotechnical engineering practices, laboratories technicians, university researchers and testing equipment manufacturers have been working together to improve triaxial testing apparatus in terms of performances, reliability and automation.

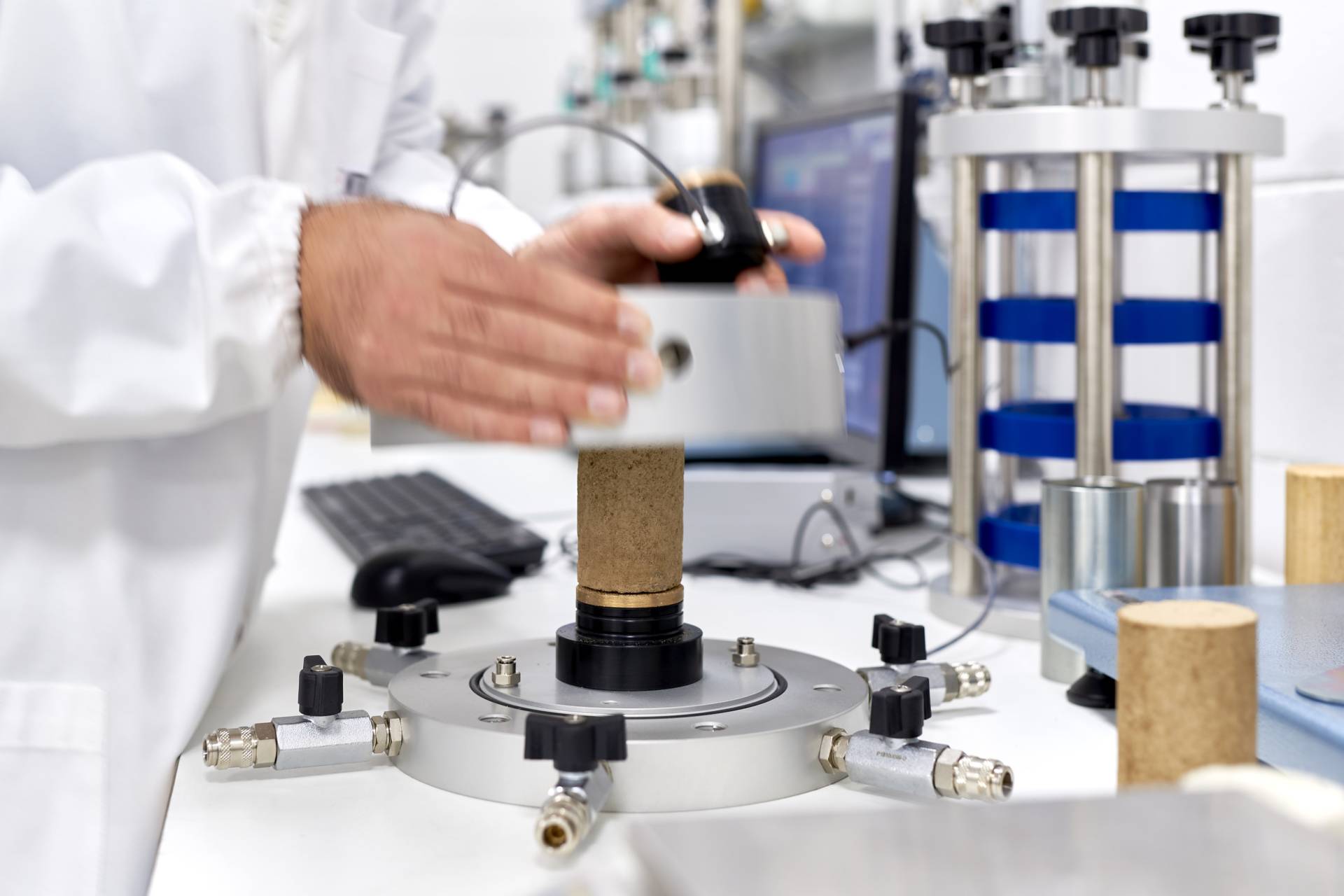

This has resulted in the development of automatic triaxial systems. These are based on closed-loop feedback control that monitors continuously the status of the main components of the triaxial system (load frame and pressure systems) in order to react to any change in the parameters pre-set for each test stage.

Here are the 10 reasons why your lab should go automatic

-

Save time

Tests run continuously 24/7 without any interruption freeing up your time to perform other duties. -

Increase accuracy

Operator error is eliminated as there is no need to collect and save data manually or perform complex calibration procedures. -

Expand testing capabilities

Close loop control of load, cell and back pressure as three independent axis makes it possible to perform more advanced test such as Stress Path or k0 — in addition to the most common Unconsolidated Undrained (UU), Consolidated Undrained CU, and Consolidated Drained (CD) tests. -

Decrease supervisory time

Limited staff supervision required since the test is managed via PC software, with automatic control of the test parameters and system limits during the whole testing procedure. This way, technicians or students can perform other activities saving valuable time. -

Easy installation

No compressed air is required as water pressure for cell and back lines are generated by pressure/volume controller instead that also allow for volume change measurements. -

Increase staff productivity

One technician is able to control, manage and acquire more than one independent triaxial test from a given PC at the same time. -

Upgrade easily

Apply your system’s automation system to Permeability and Unsaturated soil testing thanks to the modular nature of automatic soil testing systems. For example, you can set-up one frame to accommodate a three cell configuration. -

FREE remote monitoring

Test monitoring and control can be done using a free remote PC control software available on the web. -

Save your lab’s space

Automated systems do away with many components required to perform triaxial testing manually and are therefore more compact saving precious lab space. -

Accessible to all

Automatic triaxial testing systems are affordable and therefore good value. Their development stem from years of continuous Research and Development from the geotechnical manufacturing industries.

Who is automatic triaxial testing for and why?

Commercial labs:

Do you want to increase your lab’s productivity by testing overnight and weekends? Automatic triaxial testing means that you can set-up test routines with accurate and repeatable results that are not affected by manually technical errors.

University: professors can run a test with students spending the required time to explain what is happening instead of taking and collecting readings whilst still having the possibility to do some manual intervention during automatic procedure.

If you have any concerns about your Triaxial system and/or need further information about automatic triaxial systems, please get in touch our dedicated team of experienced geotechnical engineers at wfsupport@controls-group.com.