Description

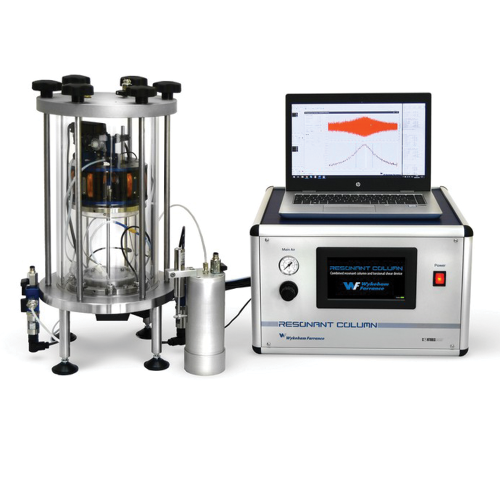

Dynatriax EmS benefits from CONTROLS Group new EmS "Electromechanical Servoactuation" technology.

EmS technology is environmentally friendly and clean to operate, requiring no compressed air or hydraulic oil. It offer excellent reliability, accurate testing and lower maintenance requirements. The intuitive design ensures it can be quickly and easily maintained, only requiring regular lubrication.

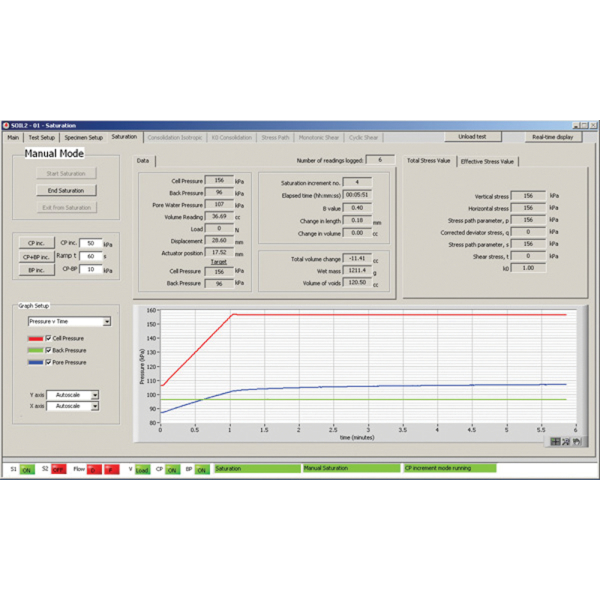

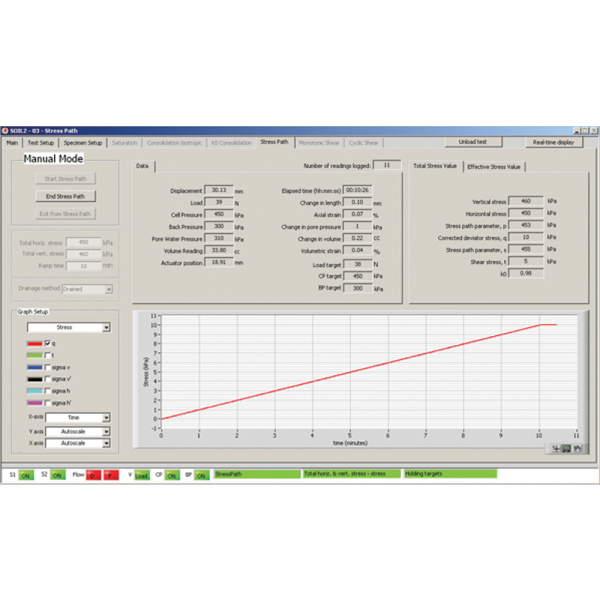

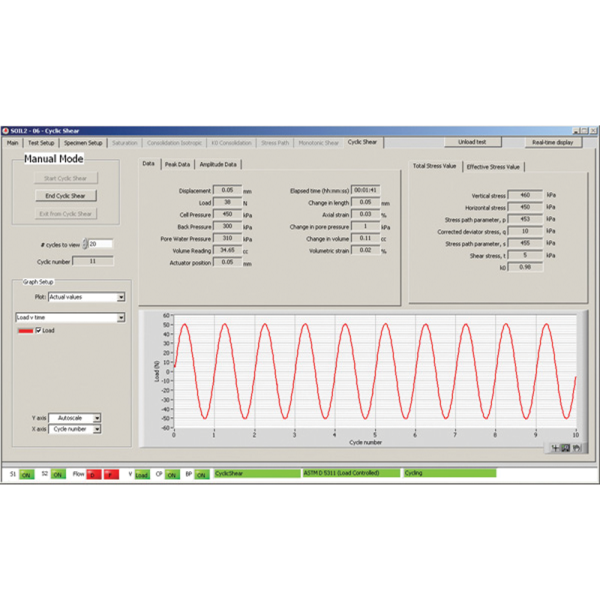

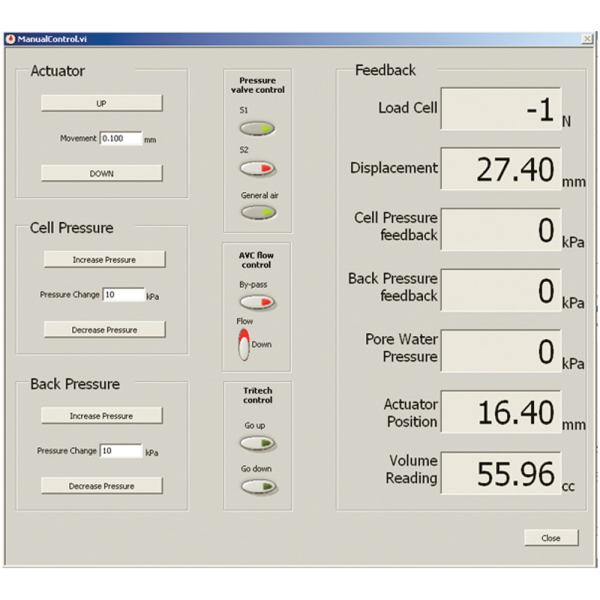

The system controls three closed-loop axes:

- Axial load/displacement

- Cell pressure up to 1000 kPa

- Back pressure up to 1000 kPa

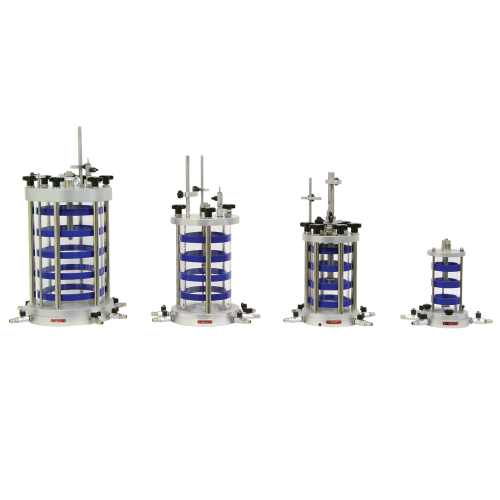

The base system includes:

- Reaction frame

- Robust 2-columns construction, stiff and compact

- Electromechanical vertical load application

- high performance motorized actuator, 15 kN capacity, backlash free and noiseless

- sophisticated PID closed-loop control, ensuring load is reached fast, smoothly and accurately and then maintained with high level of accuracy. The submersible load cell delivers high accuracy from the lowest values

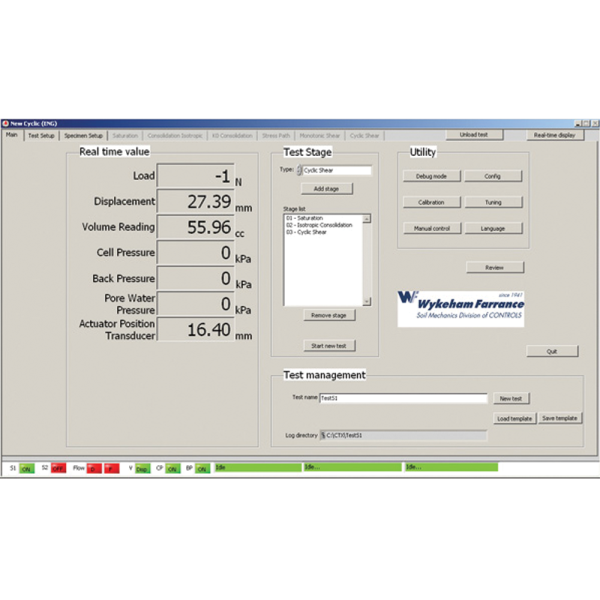

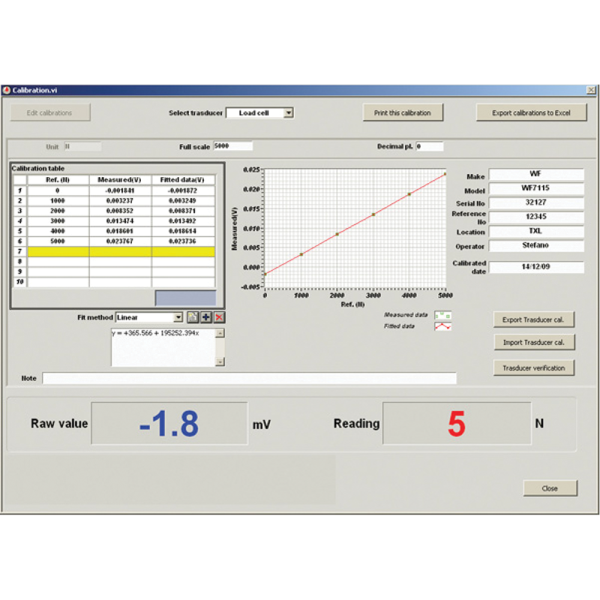

- Data acquisition, process and control

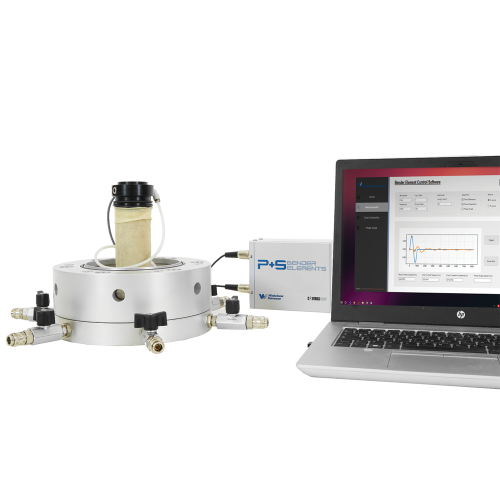

The CDC manages up to 3 closed loop axes (axial load/displacement, cell and back pressure) with an effective loop rate of 10 kHz and performs the test completely automatically including the on/off valves for the drainage line and for the air supply to the triaxial cell. It is linked to the PC via LAN/Ethernet link (1 Gbit/s) and comes with 16 transducer ports (real resolution 16 bit).

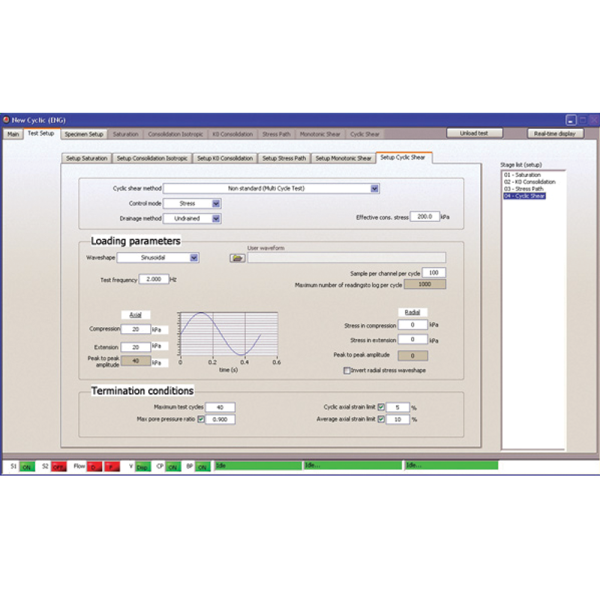

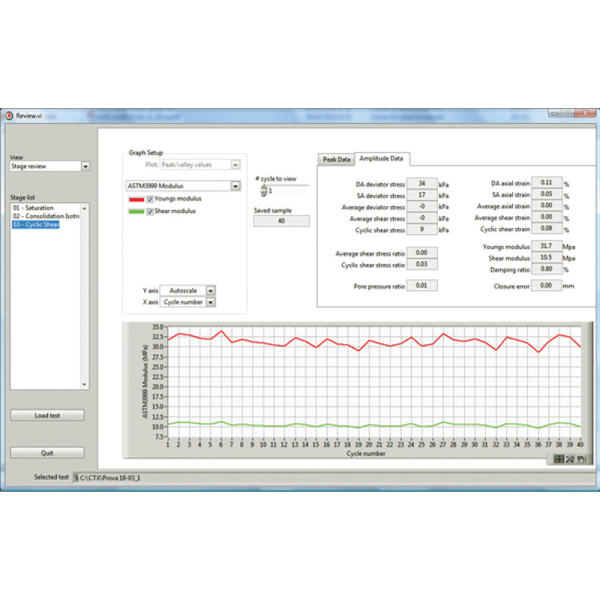

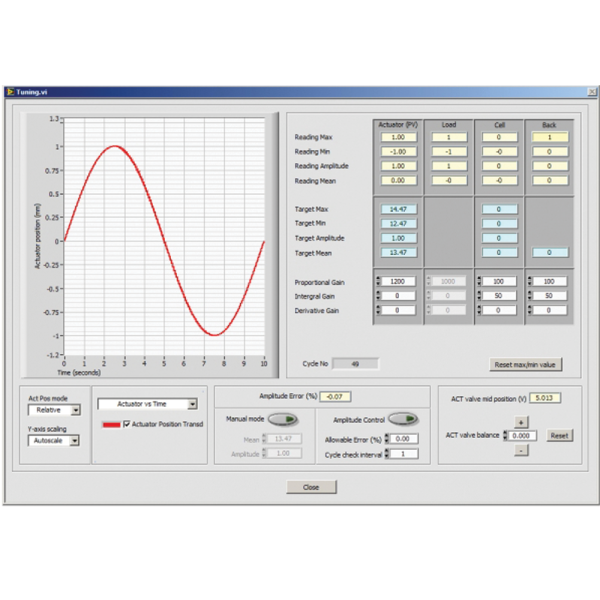

- PID control

An extremely efficient algorithm with larger gain ranges gives enhanced sensitivity, making it easier to tune the system and achieving a more accurate wave shapes.

Recently added features include manual and automatic amplitude control which compensate for small changes that may occupr in the system during cycling, ensuring that the required peaks are consistently reached. The improved tuning panel, with its more user-friendly interface, provdes all the tools necessary to optimize the system control during static and cyclic test stages.

Recently added features include manual and automatic amplitude control which compensate for small changes that may occupr in the system during cycling, ensuring that the required peaks are consistently reached. The improved tuning panel, with its more user-friendly interface, provdes all the tools necessary to optimize the system control during static and cyclic test stages.

For a complete test configuration please contact our team of specialist.