Description

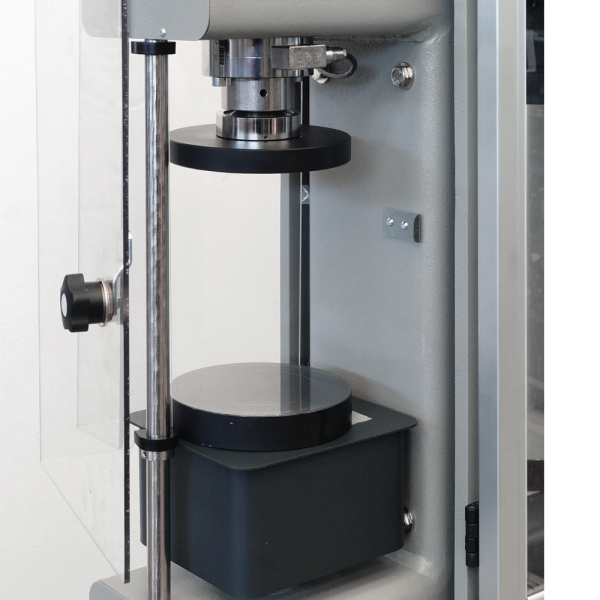

These Multipurpose compression / flexure testers have been designed for various applications in which a limited maximum load is requested, together with a large testing space. They are suitable to determinate compressive strength on lightweight concrete, soil-cement specimen, high strength cement and refractory specimens.

The large testing space is ideal for performing, with the suitable accessories, splitting tests and flexural tests on concrete specimens.

The large testing space is ideal for performing, with the suitable accessories, splitting tests and flexural tests on concrete specimens.

They are available in the two different versions:

single compression station, 500 kN or 600 kN cap.:

for compression tests on low strength specimens. The Class 1 accuracy can be extended from 1% of testing machine full scale with special calibration procedures (see Upgrading Option and Technical Specifications).

double station model, 600/15 kN or 500/15 kN cap.:

extends the possible applications to flexural tests on cement and compression tests on low strength specimens. The Class 1 accuracy can be extended with special calibration procedures (see Upgrading Option and Technical Specifications).

single compression station, 500 kN or 600 kN cap.:

for compression tests on low strength specimens. The Class 1 accuracy can be extended from 1% of testing machine full scale with special calibration procedures (see Upgrading Option and Technical Specifications).

double station model, 600/15 kN or 500/15 kN cap.:

extends the possible applications to flexural tests on cement and compression tests on low strength specimens. The Class 1 accuracy can be extended with special calibration procedures (see Upgrading Option and Technical Specifications).

Frames

High rigidity solid one piece steel frame. Spherical seat allows free alignment at the initial contact with the specimen.

Compression platens

See table. Traceable certificate of surface hardness available on request.

PILOT PRO, Automatic power and control system

See technical specifications.

Safety features

Includes: Max. pressure valve to avoid machine overloading; piston travel limit switch; emergency stop button; front door and rear transparent fragment guard on the compression station. Fragment guard for flexure station is available as optional (see Accessories).