Description

Introduction

When testing concrete cylinder specimens it is essential that the two ends are perfectly flat. This range of equipment allows the ends of the various sizes of concrete cylinders or cores to be capped using the sulphur capping compound.

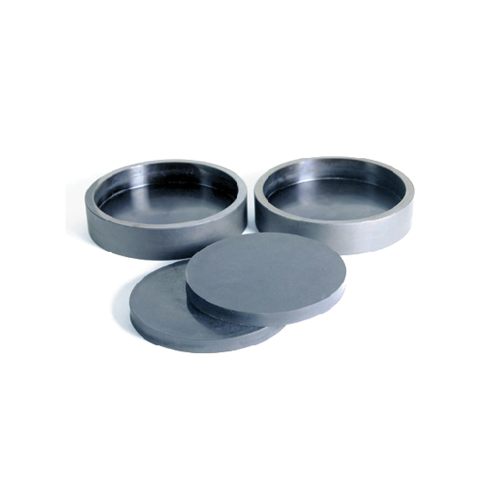

Cylinder cappers

Used to assure plane end surfaces perpendicular to the axis of the cylinder during the capping. Base and capping plate machined from steel. Guide is machined from cast aluminium or steel.

Cylinder carriers

A simple accessory for an easy handling of specimens. Only available for dia. 150 mm (6”x12”9 and 160x320 mm sizes.

Capping compound

The compound is a mixture of sulphur and mineral filler to give a high finish and performance.

Melting pot

Used to melt the capping compound. The temperature is set and maintained at the desired value. Adjustable electronic thermoregulator and pilot lamp fully isolated conforming to CE requirement.

- Capacity: 5l approx.

- Temperature range: from +30 to 150°C

- Power: 700 W

- Dimensions:

internal 200 mm dia.160 mm depth

external 285 mm dia.x 275 mm high - Weight approx.: 2.7 kg

Capping plate for concrete blocks

Used for capping concrete blocks with cement paste. 500x300 mm, 20 mm thick, made from steel, accurately machined. Protected against corrosion.