SuperPave™-type volumetric and asphalt mixture design and performance-based testing, is used in many countries and territories worldwide. Fundamentally, the SuperPave™ program stems from the need to create higher performing, longer lasting pavements that deliver better value for money for highway authorities and society in general.

This article is an introduction to the first instalment of IPC Global's Educational Series about SuperPave™ expertly prepared to help you understand the SuperPave™ type performance-based testing & design fundamentals.

What are today’s asphalt testing’s current situation and challenges?

Roads: vital for development and growth

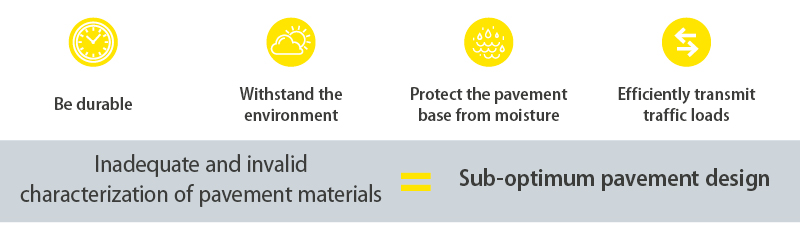

Highway pavements are essential for the safe, comfortable and rapid transportation of people and goods. Therefore, road pavements must be, among other things, durable, able to withstand the environment i.e. scorching sun, freezing temperatures, and protect the pavement base from moisture; while efficiently transmitting traffic loads to the road-base and underlying prepared soil subgrade.

Due to changes in material properties, traffic conditions, economic and environmental factors; accurate and insightful testing of asphalt pavement materials has never been so important. However, traditional empirical design and volumetric-only testing fail to properly evaluate how asphalt mixtures (mixes) and pavements might perform in real-world traffic speed and climatic conditions. While these methods can be used for lower volume and less trafficked pavements, they lack the reliability for higher-use pavements.

Traditional methods also fail to establish the fundamental materials properties needed for sophisticated pavement design models to create optimized pavements.

Consequently, inadequate and invalid characterization of pavement materials leads to sub-optimum pavement design with an increased risk of costly over-engineering or early pavement failure due to under-engineering. This may not only create additional construction and reconstruction costs but also increase:

- poor public perception of agencies

- traffic disruption,

- accidents,

- road trauma,

- vehicle wear & damage and;

- fuel consumption

A need for accurate pavement materials testing

Increasing heavy vehicle traffic, higher vehicle loads and changes to asphalt (bitumen) properties – plus developments in pavement materials such as the use of polymer modified bitumen, reclaimed asphalt pavement, recycled tire rubber and marginal materials – have resulted in significant changes to asphalt mixture and pavement performance. However, insufficient knowledge of the performance of new asphalt mixes prevents its proper and effective inclusion in pavement designs. The answer is not to ban all new materials but develop a testing plan to evaluate and encourage innovation and better performance pavements.

Roads must...

Highway pavements are essential for the safe, comfortable and rapid transportation of people & goods. Today, the increase of heavy vehicle traffic, loads and the evolution of asphalt (bitumen) mixtures have resulted in significant changes to asphalt mixture and pavement performance.

Watch this short animation

Asphalt is a complex, viscoelastic material.

Its mechanical properties change under different loading frequencies (traffic speed) and temperature conditions (climate). Therefore, proper characterization of an asphalt mixture’s response to different real-world conditions is critical to predicting performance over the pavement’s lifetime. For example, while one mixture design may work well for a high-speed highway, it may fail when also placed in an intersection where slow and static loads exist.

Traditional materials characterization methodologies, such as Marshall mixture design, use rudimentary empirical tests that simplistically assume materials behave consistently regardless of environmental or traffic conditions. Although they have historically served the industry well when coupled with volumetric analysis (air voids, voids in the mineral aggregate, dust proportion, etc.), changes as highlighted above mean these assumptions are no longer appropriate.

There is a new approach…Performance-based testing.

Read the full white paper. Get your copy now by registering on the right.