Whether we like it or not, automation is becoming more prevalent in our day-to-day lives. Every time we drive through a toll on the motorway, hop on a bus or a train, fill up with fuel or receive a reminder email, some form of automation is happening in the background. And it’s all designed to make our lives easier in some way.

It seems inevitable that this journey towards automation and the associated application of the Internet of Things (IoT) is speeding up. The ongoing Covid-19 crisis has reinforced this trend, and if anything has expediated the need for automation in certain areas of our lives.

But is the materials testing industry scared of automation? Yes – we believe it is!

In many cases, construction materials laboratories have resisted automating their testing processes due to the perception that the testing equipment is more expensive. Plus, there’s the added fear of moving on from the ‘tried and trusted’ traditional methodologies and testing processes that we’re used to.

This is a shame, because there are many activities within a construction materials laboratory that require the intervention of a specialized operator. Many processes can benefit from the advantages of testing automation that, more often than not, would compensate for the difference in the initial higher capital investment of the testing equipment

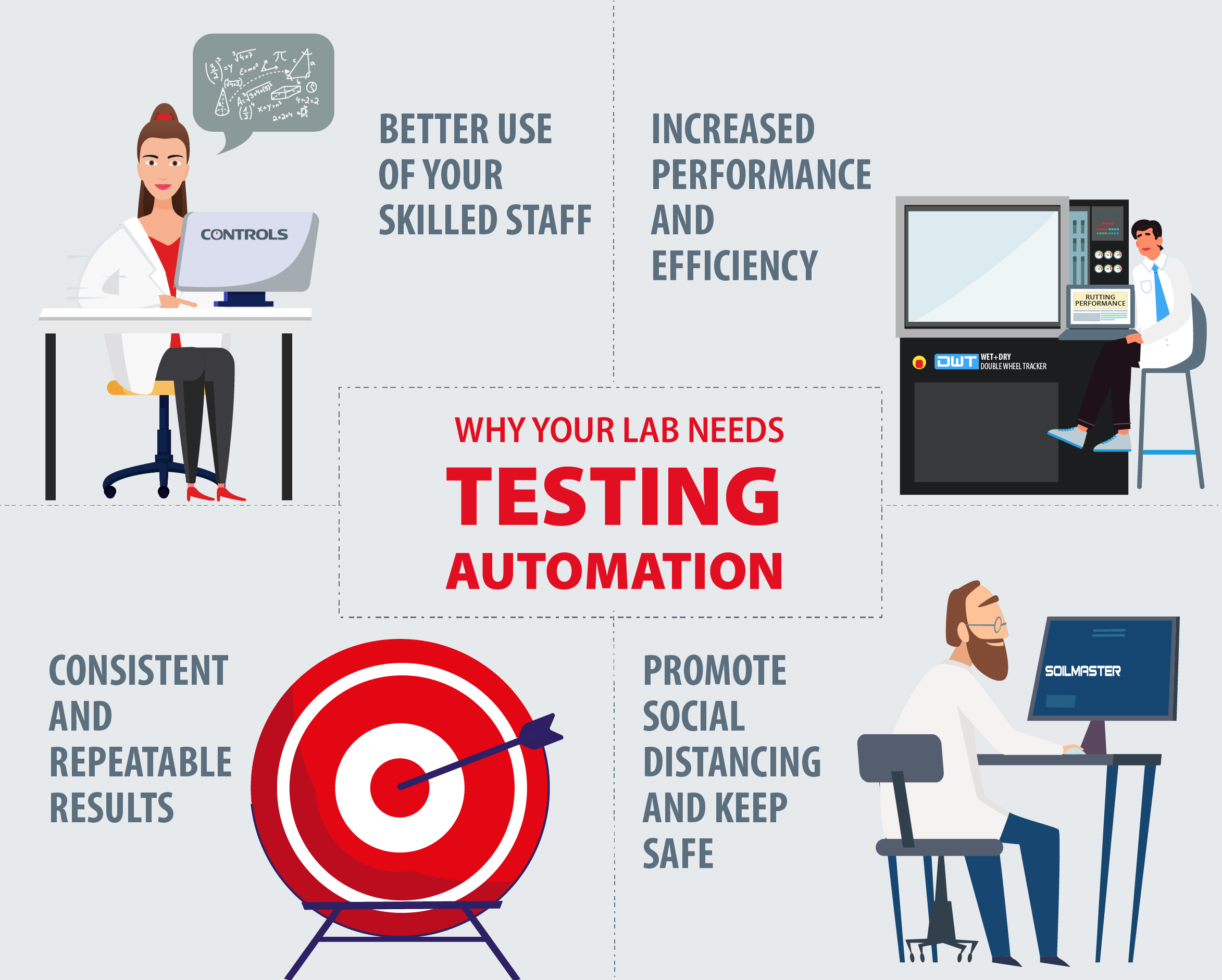

Let’s consider some of these benefits in a little more detail:

Better use of your skilled staff: Deploying automation enables many tasks to be performed by a lesser-skilled operator, freeing the time of your experienced engineers or technicians to be deployed on higher value activities.

Increased performance and efficiency: As less manual interventions such as data entry and valve adjustments are required, the number of possible errors that can stem from mis-communications between various operators is greatly reduced. This also reduces the possibility of human errors.

Consistent and repeatable results: Automated processes will inevitably improve the consistency and accuracy of results, repeatability and overall data integrity.

Promotes social distancing to keep safe: Automation means that fewer operators are needed to perform a test, and manual operations such as adjusting valves, monitoring load control, are almost removed. This makes it much easier for a Lab Manager to implement safe social distance rules, given the current climate we are all becoming used to.

What’s the status of automation for specimen preparation?

Construction materials testing laboratories that compacts specimens for Proctor or Marshall tests manually are hard to find these days. It is much more common to use automatic compactors or gyratory compactors which, in addition to improving the compaction itself and repeatability in the preparation of samples, not only free operators from carrying out tedious and time-consuming tasks, but also help avoid possible damage linked to manual compaction. However, while the application of automation to these sample preparation processes has become widespread, its implementation is less so in test and measurement systems where semi-automatic or even manual systems still steal the show. Looking at the main construction materials usually tested in laboratories, we can see that their implementation is somewhat hap-hazard.

Automation applications in soil mechanics still have a long way to go…

Based on our experiences of visiting countless soil mechanics laboratories, it still surprises me to think that longstanding tests such as soil mechanics tests (consolidation, shear, triaxial soil) requiring continuous data collection and monitoring are still not fully automated in most laboratories.

The loss and/or inconsistency of data in these tests means that they have to be performed several times, thus wasting a lot of time - hours for sample preparation; days and in some cases weeks for actual testing. Although automatic data collection systems (via dataloggers) have been generally widely adopted, in many cases the testing process is still manual or semi-automatic. Operators have to interact through the various phases of the test (saturation, consolidation, failure) by opening and closing valves manually. This intervention generates numerous and varied interactions where errors can creep in and compromise the accuracy of the results.

The implementation of automated systems such as Automatic Computerized Oedometer (ACE EmS), Automatic Shear Testing Machine (Shearmatic EmS) or Automatic Triaxial Tests System (Autotriax2), is a huge benefit not only for advanced laboratories, universities or research entities, but also for contractors or commercial laboratories alike.

What about automation in concrete, cement and other masonry materials testing?

These are certainly the most-tested construction materials today. With the exception of special or advanced tests, such as Modulus of Elasticity (MOE) and displacement-controlled tests (Fiber-reinforced Concrete or Shotcrete), the usual standard compression and flexural tests are quick. And in many laboratories, hundreds of samples are tested daily.

Adhering to International Standards

As with other brittle materials, concrete displays a different behavior under high rates of loading than under a slow or static loading rate. In particular, strength increases as rate of loading increases. This is mainly related to creep mechanism allowing strain increase in time and the appearance of microcracking.

For this reason, the main International Standards require to apply a specific load rate up to specimen failure within a strict tolerance.

Automatic machines apply the load rate strictly according to Standards’ requirements, thus leading to accurate and reliable measurement of concrete strength, without affections due to operator intervention.

Furthermore, the stress-versus-time graph can be plotted and the average load rate applied during the test is calculated at failure, thus proving the test has been performed within Standard specs.

So not only is the reliability of results improved (application of correct load rate), but also data integrity (direct import of sample dimensions and weight by using measurements devices connected to the machine) and traceability (integration with LIMS, specimen identification via barcodes, etc.). These are all of enormous value to a laboratory, its staff and customers.

Moreover, today the research and application of modern electronic and hydraulic equipment has allowed the development of automatic machines for compression and flexural tests on concrete, cement, mortar and other masonry materials, conforming to both EN-link and ASTM and AASHTO standards at prices similar to those of traditional semi-automatic systems.

Automation also plays an important role in performing advanced test methods. Historically, these tests were mostly carried out in universities or research laboratories. But today, they are becoming more and more popular.

The use of an automatic compression machine is helpful because the machine carries out these critical tests without human intervention. It’s no longer necessary to have a highly qualified, expert technician to perform these tests and calculate the final results. With automation, these can be calculated by the software according to the main International Standards.

In the meantime, automatic asphalt testing is moving along at pace…

In asphalt laboratories, the process of adoption of fully automated systems has been quite popular in the last few years, but for different reasons.

Several studies highlighted a critical lack of repeatability in traditional tests for both binder and asphalt mix. This led to the creation of performance-based methods – like SuperPaveTM – that rely very much on automation to be efficient and reliable.

For example, in Binder Performance Grading, tests like penetration and softening points — still popular as a manual test – have been replaced by fully automated tests like Pressure Aging Vessel, Dynamic Shear Rheometer and Bending Beam Rheometer.

The same applies to asphalt mix performance testing. With a fully automated testing system — such as the last generation Hamburge Wheel Trackers or Asphalt Mixture Performance Tester (AMPT Pro) for dynamic testing — the possibility to automatically set the test parameters to a higher data resolution than manual models, makes results repeatable and affordable.

So what does this mean for Asphalt Testing? Firstly, automation streamlines the operations of a laboratory. Take IPC Global’s DWT Hamburg Wheel Tracker as an example. It allows you to program both water or air preheating so that when the sample is conditioned, the test starts automatically.

This has two huge advantages:

- The machine doesn’t have to work so hard and requires less long-term maintenance; and

- It eliminates the downtime typically associated with asphalt mix conditioning, freeing the operator to perform other more important tasks.

Secondly, automation makes extracting binders quicker and more efficient. Traditional solvent extraction methods rely on a manual process. This meant tests are slow to complete and create hazardous situations, due to the toxicity of chlorinated solvents used in this operation.

The popularity of closed-loop fully automated systems, like the Hot Mix Asphalt Automatic Closed Loop Extractor (PAVELAB50 or PaveAnalyzer), not only improves the binder content result quality, but it solves a critical safety and environmental issue laboratories are facing. The fully sealed system avoids the emissions of solvent vapors in the laboratory (and the use of hoods and operators’ protection systems) while at the same time allows almost 100% of the used solvent to be recycled, with obvious economic and environmental advantages.

Conclusion

There is little doubt about the convenience of implementing these systems in an industry based on the control and accuracy of the measurements that will serve as the basis for the construction of the structures that affect so many people.

In summary, automation in construction materials testing can have a huge impact on your lab operations. From a human point of view, it frees us from tedious and time-consuming testing. From a technical point of view, anyone can be an expert testing technician as results are reliable and accurate. And finally, the level of interaction between operators is decreased helping everyone stay safe in this new world we’re now living in.