Description

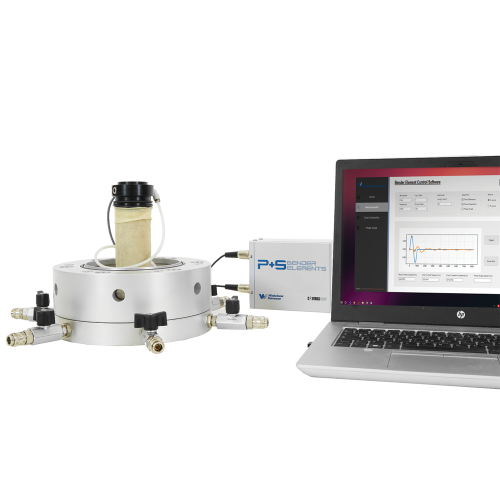

Revolutionary, all-in-one automatic triaxial testing system integrating the many components of triaxial testing into one, single compact system. Designed to make triaxial testing easier than ever before, the AUTOTRIAXQube will fit neatly in any laboratory and compliment your existing testing capability.

Secure Triaxial Cell Lifting System

The new lifting mechanism allows the operator to raise the cell to its highest position and rotate it through 90 degrees, until it’s safely held in place with a magnetic latch. This removes the need to lift the total weight of the cell while freeing space on the work bench for sample preparation tools.

Built-in Ingenious Hydraulic System

Speeds up the time required to set-up the system correctly (water circuit saturation, pressure system and triaxial cell ) avoiding any possible damage to the sample already positioned in the triaxial cell.

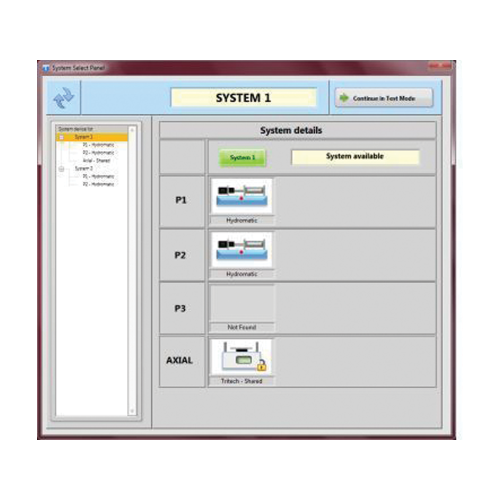

User-friendly Software

The user-friendly software and desktop PC* allow the operator to control all phases of testing over a fast Ethernet connection. The AUTOTRIAXQube can also connect using Wi-Fi which is useful for remote training and support. If you already use our flexible and renowned AUTOTRIAX software as part of your existing system, there is no need to invest in any additional software as the AUTOTRIAXQube can easily be integrated and controlled as an independent system by your existing PC and software:

- Effective/total stress: (CU/CAU**,CD/CAD**, UU) (Inclueded in the machine)

- Stress path (to be ordered separately)

- k0test (to be ordered separately)

* To be ordered separately. Please note that an optional all-in-one PC model is also available. ; ** Anisotropic consolidation according to EN 17892:9 is available. For anisotropic consolidation, a vacuum top cap is required.

Universal Accessories Compatibility

All existing accessories already in use with the 70 mm banded triaxial cell (28-WF4070) are compatible with the AUTOTRIAXQube. See Triaxial Cell Accessories Selector.

Additional Testing with Optional Upgrades

- Permeability test (Please refer to accessories)

- Unconfined test (Please refer to accessories)

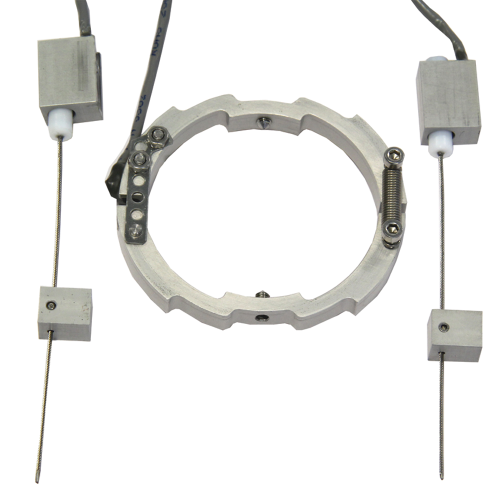

- Bender elements (Please refer to related products)

- On Sample (Please refer to accessories)